7. Use Cases

This chapter describes use cases that show how the voraus.core can be used to setup different automation solutions in conjunction with the voraus.apps. Through these use cases, you can gain a clear understanding of how the voraus software stack is utilized to address your needs and how easy it is to create solutions for all applications while also adjusting and optimizing your entire automation continuously during the whole operation lifetime.

7.1. Vision Based Pick and Place with a Conveyor Belt on KUKA

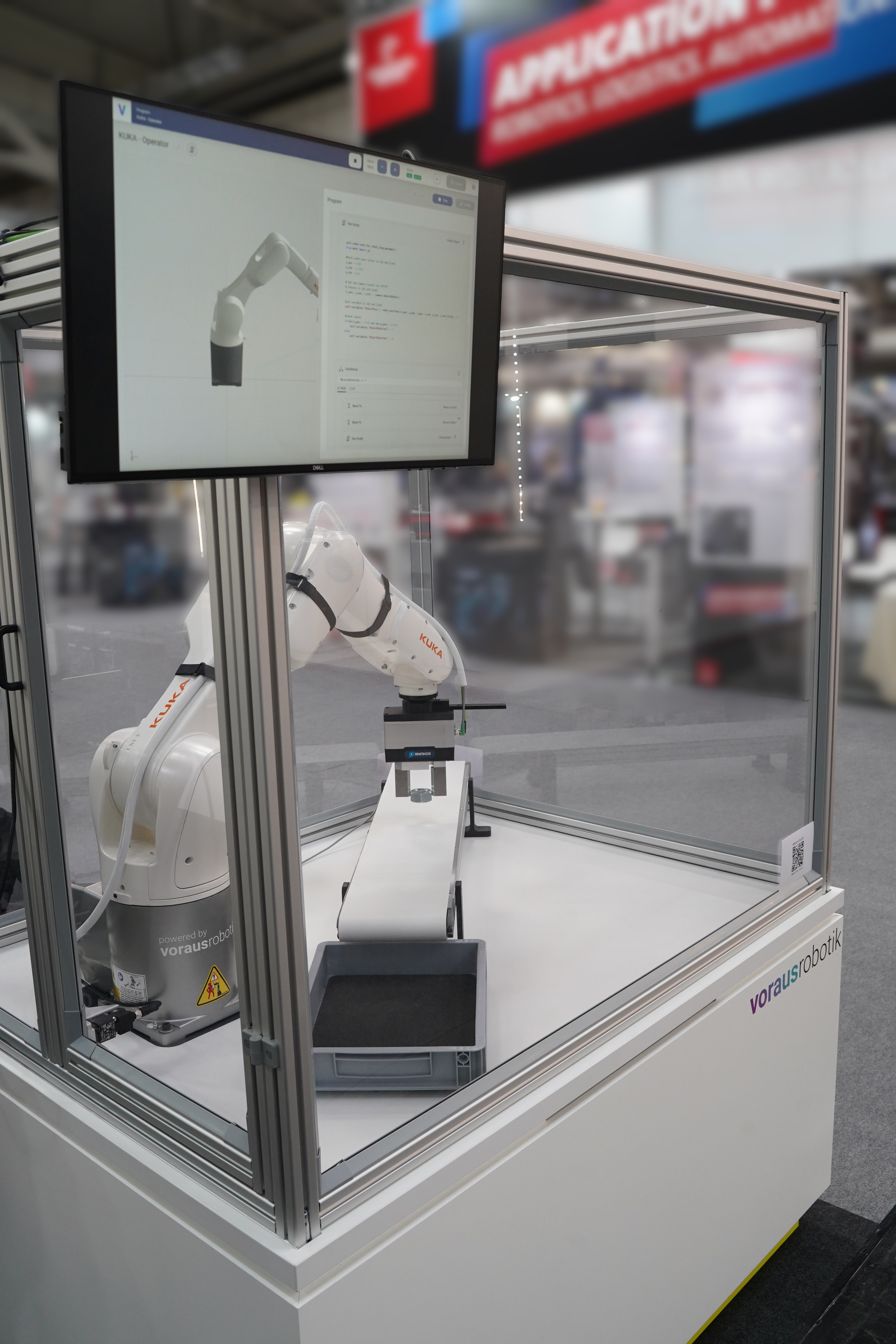

This tutorial will demonstrate how to create a vision based pick and place application with the voraus.operator like Fig. 94. The application uses a Sensopart V20-OB-A2-W12 camera for the vision based pose estimation that is mounted above the trace. A SCHUNK EGK 50 gripper and a Vetter conveyor belt FR-40-200-1000-10 controlled by a Beckhoff EL4004 4-channel analog output terminal are both connected via EtherCAT. The application is implemented on a KUKA robot.

Fig. 94 Vision Based Pick and Place Application

7.1.1. Getting Started

Requirements

voraus products:

The voraus components and their purpose in this application is shown below:

graph LR

subgraph voraus.ipc

direction TB

ve["voraus.app //EtherCAT"]

subgraph vc["voraus.core //KUKA"]

vo["voraus.operator"]

end

end

subgraph EtherCAT Fieldbus

direction LR

ao["Analog Out"]

ao --> gripper["Gripper"]

end

cam["Camera"]

vc --TCP trigger--> cam

cam --position--> vc

ve --process data--> ao

vc --control--> kuka["KUKA Robot"]

ao --voltage--> conv["Conveyor Belt"]

User --program--> vo

Setup:

Prepare the camera following the Tutorial: How to integrate a SensoPart camera with the voraus.operator.

Connect the EtherCAT devices with the following topology:

voraus.ipc ├── Beckhoff EK1100 bus coupler │ ├── Beckhoff EL1008 digital inputs (optional) │ ├── Beckhoff EL2008 digital outputs (optional) │ └── Beckhoff EL4004 analog outputs └── SCHUNK EGK 50Connect the PIN for the speed specification of the conveyor belt to analog output 1 of the EL4004 terminal.

Get the software package including the ESI file from the download section from the SCHUNK Product page. Extract and copy the ESI file to your TwinCAT installation path (default: “C:\TwinCAT\3.1\Config\Io\EtherCAT”).

7.1.2. Implementation Steps

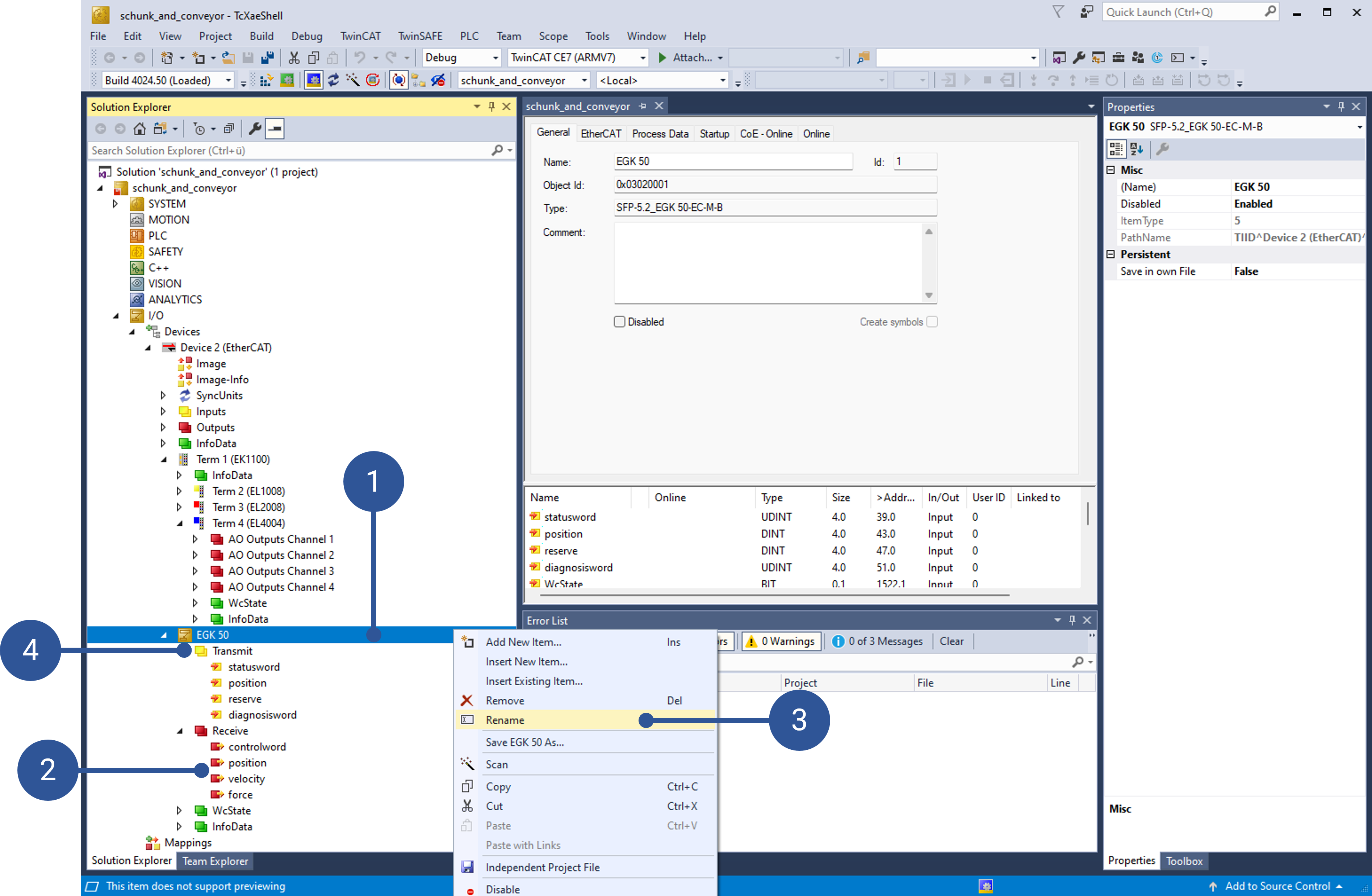

Follow the steps from voraus.app //EtherCAT: Digital IO Example to create an ENI File using TwinCAT and setup the voraus.app //EtherCAT. During these steps autogenerated python code will be created from the device descriptions. For the used SCHUNK gripper the device description looks like shown in Fig. 95.

Fig. 95 SCHUNK EGK 50 Device Description

To increase the readability in the resulting code you can edit the naming. Thus, you can right-click on the Device Name or a process data obejct (PDO) name (Fig. 96/➊ + ➋) and then select “Rename” (Fig. 96/➌). To rename the PDO groups (Fig. 96/➍) you need to perform two consecutive single clicks.

Fig. 96 Rename Device and PDOs

The resulting autogenerated code looks like this:

1"""API for Schunk EGK 50 Gripper and Conveyor."""

2

3from voraus_ecat import EtherCAT, ProcessData, pdo

4import time

5from enum import IntEnum

6

7

8class Inputs(ProcessData):

9 """Defines process inputs."""

10

11 def __init__(self) -> None:

12 """Initializes process inputs."""

13 super().__init__()

14

15 self.egk_50_transmit_statusword = pdo.Unsigned32("1:EGK 50.Transmit.statusword")

16 self.egk_50_transmit_position = pdo.Integer32("1:EGK 50.Transmit.position")

17 self.egk_50_transmit_reserve = pdo.Integer32("1:EGK 50.Transmit.reserve")

18 self.egk_50_transmit_diagnosisword = pdo.Unsigned32("1:EGK 50.Transmit.diagnosisword")

19 self.term_2_el1008_channel_1_input = pdo.Bit1("1:Term 2 (EL1008).Channel 1.Input")

20 self.term_2_el1008_channel_2_input = pdo.Bit1("1:Term 2 (EL1008).Channel 2.Input")

21 self.term_2_el1008_channel_3_input = pdo.Bit1("1:Term 2 (EL1008).Channel 3.Input")

22 self.term_2_el1008_channel_4_input = pdo.Bit1("1:Term 2 (EL1008).Channel 4.Input")

23 self.term_2_el1008_channel_5_input = pdo.Bit1("1:Term 2 (EL1008).Channel 5.Input")

24 self.term_2_el1008_channel_6_input = pdo.Bit1("1:Term 2 (EL1008).Channel 6.Input")

25 self.term_2_el1008_channel_7_input = pdo.Bit1("1:Term 2 (EL1008).Channel 7.Input")

26 self.term_2_el1008_channel_8_input = pdo.Bit1("1:Term 2 (EL1008).Channel 8.Input")

27

28

29class Outputs(ProcessData):

30 """Defines process outputs."""

31

32 def __init__(self) -> None:

33 """Initializes process outputs."""

34 super().__init__()

35

36 self.egk_50_receive_controlword = pdo.Unsigned32("1:EGK 50.Receive.controlword")

37 self.egk_50_receive_position = pdo.Integer32("1:EGK 50.Receive.position")

38 self.egk_50_receive_velocity = pdo.Integer32("1:EGK 50.Receive.velocity")

39 self.egk_50_receive_force = pdo.Integer32("1:EGK 50.Receive.force")

40 self.term_4_el4004_ao_outputs_channel_1_analog_output = pdo.Integer16("1:Term 4 (EL4004).AO Outputs Channel 1.Analog output")

41 self.term_4_el4004_ao_outputs_channel_2_analog_output = pdo.Integer16("1:Term 4 (EL4004).AO Outputs Channel 2.Analog output")

42 self.term_4_el4004_ao_outputs_channel_3_analog_output = pdo.Integer16("1:Term 4 (EL4004).AO Outputs Channel 3.Analog output")

43 self.term_4_el4004_ao_outputs_channel_4_analog_output = pdo.Integer16("1:Term 4 (EL4004).AO Outputs Channel 4.Analog output")

44 self.term_3_el2008_channel_1_output = pdo.Bit1("1:Term 3 (EL2008).Channel 1.Output")

45 self.term_3_el2008_channel_2_output = pdo.Bit1("1:Term 3 (EL2008).Channel 2.Output")

46 self.term_3_el2008_channel_3_output = pdo.Bit1("1:Term 3 (EL2008).Channel 3.Output")

47 self.term_3_el2008_channel_4_output = pdo.Bit1("1:Term 3 (EL2008).Channel 4.Output")

48 self.term_3_el2008_channel_5_output = pdo.Bit1("1:Term 3 (EL2008).Channel 5.Output")

49 self.term_3_el2008_channel_6_output = pdo.Bit1("1:Term 3 (EL2008).Channel 6.Output")

50 self.term_3_el2008_channel_7_output = pdo.Bit1("1:Term 3 (EL2008).Channel 7.Output")

51 self.term_3_el2008_channel_8_output = pdo.Bit1("1:Term 3 (EL2008).Channel 8.Output")

The Inputs and Outputs of the SCHUNK gripper are accessible with the variables in Lines 15 to 18 & 36 to 39, respectively. The variable to control the conveyor is the one in Line 40. Add this code to the voraus.operator program from Sensopart with Operator: Implementation Steps as a Run Script command. This enables other commands to use the voraus.app //EtherCAT within the program.

Add another Run Script command for the Conveyor class, which sets the analog output to control the conveyor’s speed (Line 8):

1from enum import IntEnum

2

3class Conveyor:

4 def __init__(self, ethercat: EtherCAT):

5 self.ethercat = ethercat

6

7 def set_voltage(self, voltage: float) -> None:

8 self.ethercat.outputs.term_4_el4004_ao_outputs_channel_1_analog_output.set(round((voltage/10)*32767))

9 ethercat.write_pdos()

10

11 def stop(self) -> None:

12 self.set_voltage(0.7)

13

14 def default_velocity(self) -> None:

15 self.set_voltage(0.0)

16

17 def set_velocity(self, velocity):

18 if velocity <= 0:

19 self.stop()

20 else:

21 voltage = min((velocity * 9) + 1, 10.0)

22 self.set_voltage(voltage)

For the SCHUNK gripper add a further Run Script command:

1import time

2from enum import IntEnum

3

4

5class EGK50:

6 MIN_TORQUE = 50 # value in %

7 MAX_TORQUE = 100

8 MIN_VELOCITY = 6250

9 MAX_VELOCITY = 130000

10

11 class ControlWord(IntEnum):

12 FAST_STOP = 0

13 STOP = 1

14 ACKNOWLEDGE = 2

15 RELEASE_FOR_MANUAL_MOVEMENT = 5

16 GRIP_DIRECTION = 7

17 RELEASE_WORKPIECE = 11

18 GRIP_WORKPIECE = 12

19 MOVE_TO_ABSOLUTE_POSITION = 13

20 MOVE_TO_RELATIVE_POSITION = 14

21 ACTIVATE_GPE = 31

22

23 class StatusWord(IntEnum):

24 READY_FOR_OPERATION = 0

25 READY_FOR_SHUTDOWN = 2

26 COMMAND_SUCCESS = 4

27 COMMAND_RECEIVE_TOGGLE = 5

28 WARNING = 6

29 ERROR = 7

30 RELEASE_FOR_MANUAL_MOVEMENT = 8

31 SOFTWARE_LIMIT_REACHED = 9

32 NO_WORKPIECE = 11

33 WORKPIECE_GRIPPED = 12

34 POSITION_REACHED = 13

35 WORKPIECE_LOST = 16

36 WRONG_WORKPIECE = 17

37 GPE = 31

38

39 def __init__(self, ethercat: EtherCAT):

40 self.ethercat = ethercat

41

42 # outupts

43 self.control_word = 0

44 self.target_position = 0

45 self.velocity = 0

46 self.torque = 0

47

48 # inputs

49 self.status_word = 0

50 self.current_position = 0

51

52 self._update()

53 self.control_word = 1 << EGK50.ControlWord.FAST_STOP # fast stop is 0 active --> set to high

54 self.velocity = MIN_VELOCITY

55 self.torque = MIN_TORQUE

56 self._update()

57 self._ack_error()

58

59 def move_to_absolute_position(self, position: int, velocity: int = MAX_VELOCITY) -> None:

60 """Move the motor to a specified position with a given velocity.

61

62 Parameters:

63 position (int): Target position in µm.

64 velocity (int): Movement speed in µm/s (default is MAX_VELOCITY).

65

66 Raises:

67 ValueError: If velocity is outside the range [MIN_VELOCITY, MAX_VELOCITY].

68 RuntimeError: If a warning or error occurs during the movement.

69 """

70 self.target_position = position

71 if velocity < self.MIN_VELOCITY:

72 raise ValueError(f"Velocity must be at least {self.MIN_VELOCITY} µm/s")

73 if velocity > self.MAX_VELOCITY:

74 raise ValueError(f"Velocity mustn't be larger than {self.MAX_VELOCITY} µm/s")

75 self.velocity = velocity

76 self.torque = 0

77 self._update()

78 self.control_word |= 1 << EGK50.ControlWord.MOVE_TO_ABSOLUTE_POSITION

79 self._update()

80 try:

81 while True:

82 self._update()

83 if self.test_statusword_bit(EGK50.StatusWord.COMMAND_SUCCESS): # done

84 self._update()

85 return

86 if self.warning_or_error_present():

87 raise RuntimeError("Failed to move to absolute position!")

88 finally:

89 self.control_word &= ~(1 << EGK50.ControlWord.MOVE_TO_ABSOLUTE_POSITION)

90 self._update()

91

92 def _ack_error(self) -> None:

93 self.control_word |= 1 << EGK50.ControlWord.ACKNOWLEDGE

94 self._update()

95 self.control_word &= ~(1 << EGK50.ControlWord.ACKNOWLEDGE)

96 self._update()

97

98 def warning_or_error_present(self) -> bool:

99 """Check if there is a warning or error present.

100

101 Returns:

102 True if a warning or error is present, False otherwise.

103 """

104 return self.test_statusword_bit(EGK50.StatusWord.WARNING) or self.test_statusword_bit(EGK50.StatusWord.ERROR)

105

106 def test_statusword_bit(self, bit: StatusWord) -> bool:

107 """Test if a specific bit is set in the status word.

108

109 Parameters:

110 bit: The bit to test in the status word.

111

112 Returns:

113 True if the specified bit is set, False otherwise.

114 """

115 return self.status_word & (1 << bit) > 0

116

117 def grip_object(self, torque: int = MIN_TORQUE) -> bool:

118 """Grip an object with the specified torque.

119

120 Args:

121 torque (int): The torque value (in percentage) to apply. Default is 50.

122

123 Returns:

124 success: Whether an object was grabbed or not

125 """

126 if torque < self.MIN_TORQUE:

127 raise ValueError("Torque must be at least 50%!")

128 if torque > self.MAX_TORQUE:

129 raise ValueError("Torque can not be larger than 100%!")

130 self.velocity = 0

131 self.torque = torque

132 self._update()

133 self.control_word |= 1 << EGK50.ControlWord.GRIP_WORKPIECE

134 self._update()

135 success = False

136 try:

137 while True:

138 self._update()

139 if self.test_statusword_bit(EGK50.StatusWord.COMMAND_SUCCESS): # done

140 self._update()

141 success = True

142 break

143 if self.test_statusword_bit(EGK50.StatusWord.NO_WORKPIECE):

144 success = False

145 break

146 if self.warning_or_error_present():

147 success = False

148 break

149 finally:

150 self.control_word &= ~(1 << EGK50.ControlWord.GRIP_WORKPIECE)

151 self._update()

152 return success

153

154 def _update(self) -> None:

155 self.ethercat.outputs.egk_50_receive_controlword.set(self.control_word)

156 self.ethercat.outputs.egk_50_receive_position.set(self.target_position)

157 self.ethercat.outputs.egk_50_receive_velocity.set(self.velocity)

158 self.ethercat.outputs.egk_50_receive_force.set(self.torque)

159 self.ethercat.write_pdos()

160 time.sleep(0.1)

161 self.ethercat.read_pdos()

162

163 self.control_word = self.ethercat.outputs.egk_50_receive_controlword.get()

164 self.target_position = self.ethercat.outputs.egk_50_receive_position.get()

165 self.velocity = self.ethercat.outputs.egk_50_receive_velocity.get()

166 self.torque = self.ethercat.outputs.egk_50_receive_force.get()

167

168 self.status_word = self.ethercat.inputs.egk_50_transmit_statusword.get()

169 self.current_position = self.ethercat.inputs.egk_50_transmit_position.get()

The controlword GRIP_WORKPIECE (Line 112) used in the method grip_object() (Line 95) is meant to

close the gripper force-based, therefore, it can deal with objects of different sizes. However, the gripper is pretty

slow in this mode. That is why opening the gripper with the faster mode MOVE_TO_ABSOLUTE_POSITION (Line 68) in

method move_to_absolute_position() (Line 59) is more convenient.

Next you can create an EtherCAT Client instance (Line 1). With an established connection to the voraus.app //EtherCAT (Line 2) you can set the master into operational state (Line 3) to cyclically update the process data. Finally you can create instances of the conveyor and the gripper class (Line 4 & 5):

1ethercat = EtherCAT(inputs=Inputs(), outputs=Outputs())

2with ethercat.connection(ETHERCAT_MASTER_OPCUA_URL):

3 ethercat.set_op_state()

4 conveyor = Conveyor(ethercat)

5 gripper = EGK50(ethercat)

Now you can add the new gripper and conveyor commands to the appropriate positions in the voraus.operator program from Sensopart with Operator: Implementation Steps. After reaching the tool position from the camera you can grip the object with:

1self.robot.wait_for_robot_stop_movement()

2

3with ethercat.connection(ETHERCAT_MASTER_OPCUA_URL):

4 gripper.grip_object()

Then you can drive to a position right over the conveyor and release the object with the following code:

1self.robot.wait_for_robot_stop_movement()

2

3with ethercat.connection(ETHERCAT_MASTER_OPCUA_URL):

4 gripper.move_to_absolute_position(60000)

and finally, start the conveyor to move the object back to the start position with:

1self.robot.wait_for_robot_stop_movement()

2

3with ethercat.connection(ETHERCAT_MASTER_OPCUA_URL):

4 conv.set_velocity(1.0)

while the robot can move back to its starting position, too. To stop the conveyor add:

1self.robot.wait_for_robot_stop_movement()

2

3with ethercat.connection(ETHERCAT_MASTER_OPCUA_URL):

4 conv.stop()